Sebetsa sa spherical self-aligning rolara

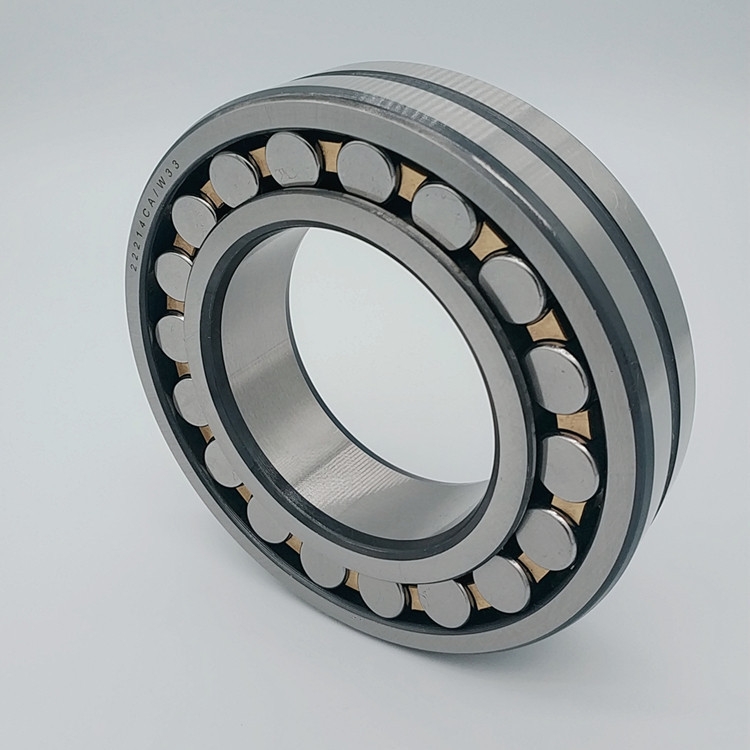

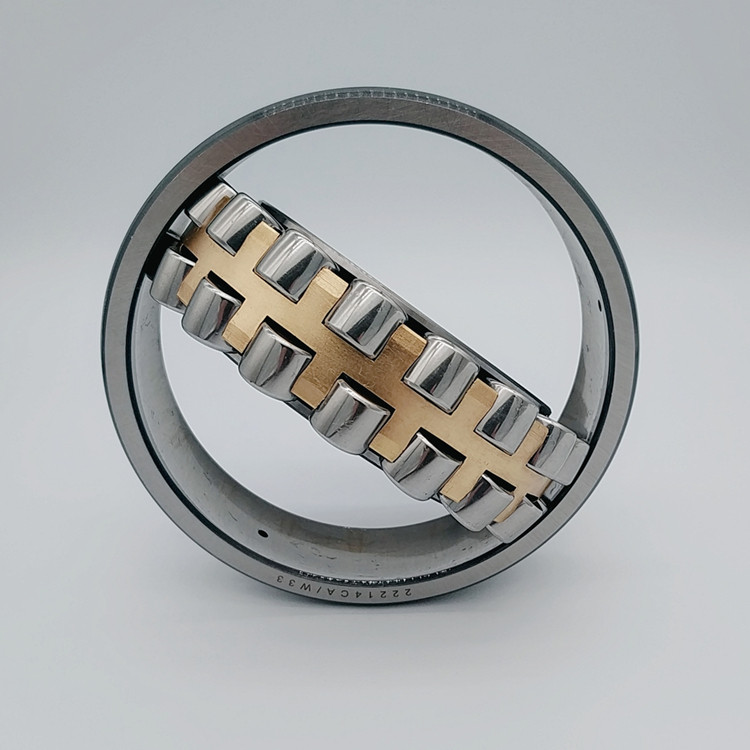

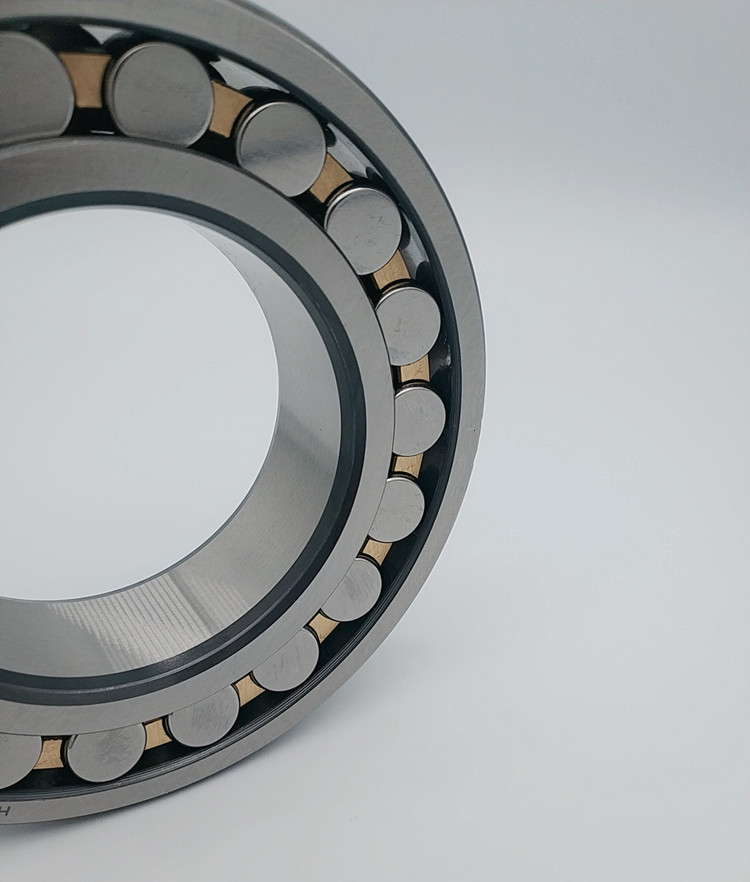

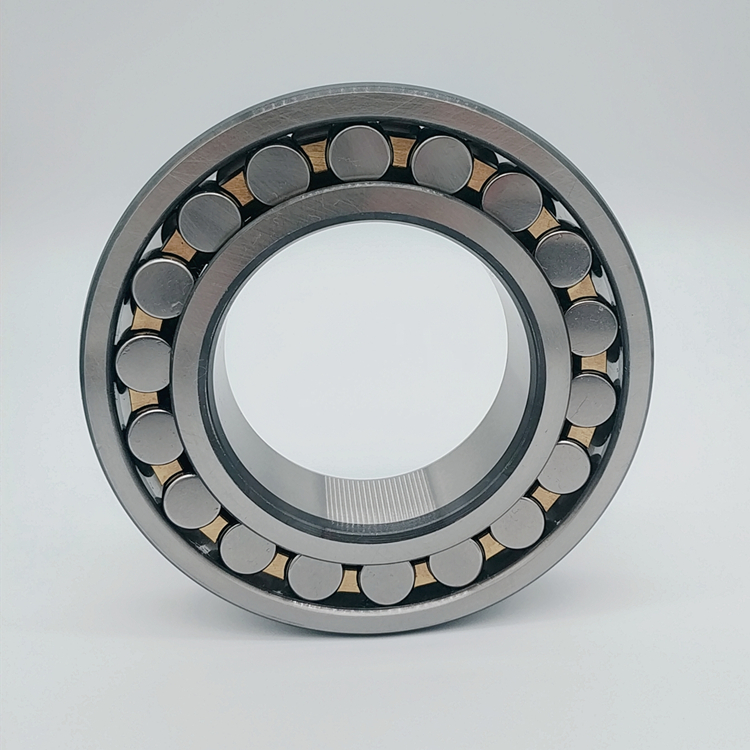

Tlhaloso ea Sehlahisoa:

Tlhaloso: selikalikoe sa ka ntle, selikalikoe sa ka hare, 'mele o pota-potileng le lesaka Reng la ka hare: lesela le ts'ehetsang Lesale la ka ntle: likarolo tse tšehetsang kapa ho phunya 'mele oa ho thella: ho thella le ho bilika Cage: arola lintho tse bilikang Melemo: ho hanyetsa likhohlano tse nyane, qalo e hlokolosi, ts'ebetso e phahameng, lubrication e bonolo. , phapanyetsano e bonolo, joalo-joalo.

Sebetsa sa rolara

Nakong ea kopano kapa ho kenya, haeba tumello ea ka hare ea li-bearings e le khōlō haholo kapa e nyenyane haholo, kapa maemong a mang, preload e phahame haholo, e ka lebisang tšenyo ea pele le ho khutsufatsa bophelo ba ho beleha.Ntle le ho fokotsa nako le tlhokomelo e theko e boima, kopano e sa lokelang le ho kenya li-bearings ho ka ba le liphello tse mpe haholoanyane, tse kang ho ama ts'ebetso ea likarolo tse ling le ho khutsufatsa bophelo ba bona ba tšebeletso.

Ho jara ke karolo ea bohlokoa ea lisebelisoa tsa mochini.Ho bohlokoa haholo ho netefatsa ts'ebetso e ntle ka ho fetisisa, mosebetsi o tšepahalang, ho kenya le ts'ebetso e nepahetseng, le tlhokomelo e nepahetseng ea ho jara.

Tšobotsi ea ho Bearing

Li-roller bearings tse ikemetseng li ka jara meroalo ea radial hammoho le meroalo ea axial ka tsela efe kapa efe.Matla a phahameng a radial, haholo-holo a loketse mosebetsi o boima kapa oa ho sisinyeha, empa ha a khone ho mamella mojaro o hloekileng oa axial.Tsela ea ka ntle ea selikalikoe sa mofuta ona e chitja, ka hona e na le ts'ebetso e ntle ea ho ikamahanya 'me e ka lefella phoso ea coaxiality.

Pontšo ea lihlahisoa

Ho paka & ho romelloa

Bearing Application

Mechini e etsang lipampiri, lisebelisoa tsa phokotso, li-axle tsa seporo sa terene, li-roller mill roller, crusher, skrini se thothomelang, mochini o hatisang, metjhini e betlang mapolanka, mefuta eohle ea lisebelisoa tsa phokotso ea indasteri, tse otlolohileng tse nang le setulo.

Mekhahlelo

| E nang le No. | Litekanyo(mm) | Boima ba kg | |||

| Cylindrical Broe | Conical Bore | d | D | B | |

| 22206 W33 | 22206 K W33 | 30 | 62 | 20 | 0.3 |

| 22207 W33 | 22207 K W33 | 35 | 72 | 23 | 0.46 |

| 21307 W33 | 21307 K W33 | 35 | 80 | 21 | 0.57 |

| 22307 W33 | 22307 K W33 | 35 | 80 | 31 | 0.78 |

| 22208 W33 | 22208 K W33 | 40 | 80 | 23 | 0.56 |

| 21308 W33 | 21308 K W33 | 40 | 90 | 23 | 0.78 |

| 22308 W33 | 22308 K W33 | 40 | 90 | 33 | 1.07 |

| 22209 W33 | 22209 K W33 | 45 | 85 | 23 | 0.61 |

| 21309 W33 | 21309 K W33 | 45 | 100 | 25 | 1.05 |

| 22309 W33 | 22309 K W33 | 45 | 100 | 36 | 1.41 |

| 22210 W33 | 22210 K W33 | 50 | 90 | 23 | 0.65 |

| 21310 W33 | 21310 K W33 | 50 | 110 | 27 | 1.36 |

| 22211 W33 | 22211 K W33 | 50 | 110 | 40 | 1.92 |

| 21311 W33 | 21311 K W33 | 55 | 100 | 25 | 0.88 |

| 22311 W33 | 22311 K W33 | 55 | 120 | 29 | 1.7 |

| 22212 W33 | 22212 K W33 | 55 | 120 | 43 | 2.7 |

| 21312 W33 | 21312 K W33 | 60 | 110 | 28 | 1.2 |

| 22312 W33 | 22312 K W33 | 60 | 130 | 31 | 2.1 |

| 22213 W33 | 22213 K W33 | 60 | 130 | 46 | 3.05 |

| 21313 W33 | 21313 K W33 | 65 | 120 | 31 | 1.56 |

| 22313 W33 | 22313 K W33 | 65 | 140 | 33 | 2.6 |

| 22214 W33 | 22214 K W33 | 65 | 140 | 48 | 3.67 |

| 21314 W33 | 21314 K W33 | 70 | 125 | 31 | 1.65 |

| 22314 W33 | 22314 K W33 | 70 | 150 | 35 | 3.1 |

| 22215 W33 | 22215 K W33 | 70 | 150 | 51 | 4.45 |

| 21315 W33 | 21315 K W33 | 75 | 130 | 31 | 1.74 |

| 21315 W33 | 21315 K W33 | 75 | 160 | 37 | 3.8 |

| 22315 W33 | 22315 K W33 | 75 | 160 | 55 | 5.44 |

| 22216 W33 | 22216 K W33 | 80 | 140 | 33 | 2.19 |

| 21316 W33 | 21316 K W33 | 80 | 170 | 39 | 4.5 |

| 22316 W33 | 22316 K W33 | 80 | 170 | 58 | 6.42 |

| 22217 W33 | 22217 K W33 | 85 | 150 | 36 | 2.75 |

| 21317 W33 | 21317 K W33 | 85 | 180 | 41 | 5.3 |

| 22317 W33 | 22317 K W33 | 85 | 180 | 60 | 7.46 |