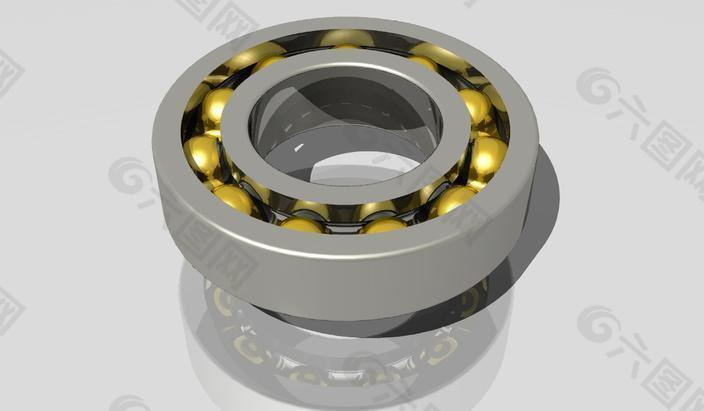

Phenomenon (1): Meroalo e fapaneng e tla hlaha ka mefuta e fapaneng ea ts'enyo ea ho roala tlas'a boemo ba ho se be le lubrication.Ha mojaro o le tlase 'me ho e-na le ho thella, letlalo le lenyenyane le hlaha.Hobane li ngata ebile li shebahala joaloka mekoti tseleng ea peiso.Re sebelisa pitting ho e hlalosa.Ha mojaro o le moholo 'me filimi ea oli e tlotsang e fetoha e tšesaane, joalo ka ho kenella ha metsi, ha tsela ea peiso e bentšitsoe tlas'a khatello, ho tla hlaha li-dimples tse bōpehileng joaloka khetla.Ha mojaro o le holimo 'me lubrication e fokola, ho tla ba le sebaka se chesang haholo tseleng ea peiso,' me ka mor'a ts'ebetso e tsoelang pele, mapetsong a pele a tla hlaha.Lisosa: - Ho se be le mafura ka lebaka la: • Ho haella ha mafura ka lebaka la: • Phepelo e sa lekaneng ea lubricant • Mocheso o phahameng haholo oa ho sebetsa • Ho kena metsing ho baka khohlano e feteletseng le khatello ea lintho tse bonahalang holim'a mabelo - Ka nako e 'ngoe ho na le litlhare tse thellang: - Eketsa mafura a mangata - Sebelisa Lilubricant tse phahameng tsa viscosity le EP e lekiloeng. li-additives hohle moo ho khonehang - Litlolo tse futhumatsang / li-bearings - Mafura a bonolo ha ho khoneha - E thibela ho kena ha metsi • Mokhathala ka lebaka la ho khathala.

Phenomenon (2): Ka mohlala, ho na le ho phunyeletsa ha likarolo tsa li-roller bearings.pina ea lente.Lebaka: Ka lebaka la ho silafala ha lubricant, joalo ka ho kena ha likaroloana tsa kantle ho naha ka lebaka la ho hloleha ha tiiso, likarolo tse jereng li apesoa sebakeng sa ho ikopanya le rolling mme geometry ea likarolo e fetoha.Karolo ea sephetho sa overloading ea sebakeng seo e boetse e amana le phetoho e sa lokelang ea li-bearings tsa tapered roller.Mehato ea ho lokisa: - Phetoho e nakong ea lubricant - Sefe ea oli - Ntlafatso ea litiiso - Ho nchafatsa litiiso tse senyehileng ka nako - Phekolo e khethehileng ea mocheso oa mehele le lirolara • Mokhathala o bakoang ke ho robeha ha lera le thata.

Phenomenon (3): Likarolo tse koahetseng holimo li na le likotoana tse kholo tsa tsela ea peiso.Lisosa: - Ho petsoha kapa karohano ea lera le thata - Moroalo o mongata haholo kapa botebo bo sa lekaneng ba lera le thata bakeng sa mojaro o fanoeng, mohlala, ka lebaka la meroalo e fosahetseng ea moralo Pheko: - Fetola botebo ba lera le thata ho ea maemong a mojaro - Qoba ho jara ho feta tekano. ho tloswa Bearing Evaluation of Running Characteristics and Damage Rolling Contact Mode 51: Ho roala libakeng tse fapaneng ho ka fetola geometry ea sebaka sa ho ikopanya le karolo ho isa moo ho jarolloang ha libaka ho lebisang ho hloleheng ho khathala.

Nako ea poso: Apr-14-2022