Tsoela pele ho kenya bolo e tebileng ea groove

Tlhaloso ea Video

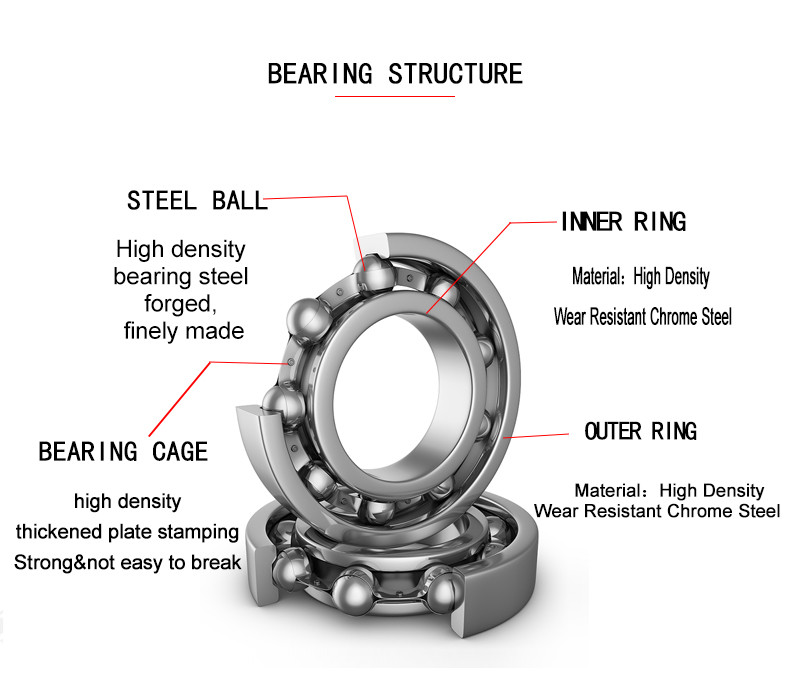

Bearing sebopeho

Deep groove ball bearing e na le sebopeho se bonolo 'me ho bonolo ho finyella ho nepahala ha tlhahiso e phahameng ha e bapisoa le mefuta e meng, kahoo e loketse tlhahiso ea bongata ka lihlopha,' me litšenyehelo tsa tlhahiso li tlaase, kahoo li tumme haholo ha li sebelisoa.Ntle le mofuta oa mantlha, ho na le meaho e fapaneng e fapaneng, joalo ka: bolo e tebileng ea groove e nang le sekoaelo sa lerōle, bolo e tebileng ea groove e nang le selikalikoe sa ho tiisa rabara, bolo ea groove e tebileng e nang le li-stop groove, bolo ea groove e tebileng e nang le mojaro o moholo. bolo notch, mela e 'meli e tebileng ea groove ball bearing.

Molemo oa rona

1, tumello ea radial e batla e le nyane, e ka jarolloa esale pele matla a fumanehang ho felisa tumello, ts'ebetso e nepahetseng e phahameng;

2. Tlas'a maemo a kakaretso, katleho ea li-rolling bearings e lekana le ea li-bearings tsa hydrodynamic lubricated, empa e phahame ho feta ea li-bearings tse tsoakiloeng;

3, bakeng sa boholo bo lekanang ba bophara ba shaft, bophara ba ho roala ho nyenyane ho feta ho thella, ho ka etsang hore mohaho oa axial oa mochine o kopane;

4. Boemo bo phahameng ba maemo, tlhahiso ea li-batch, tšebeliso e fokolang ea lubricant, ho tiisa habonolo, tlhokomelo e bonolo, ha ho hlokahale tšepe e se nang ferrous le theko e tlaase.

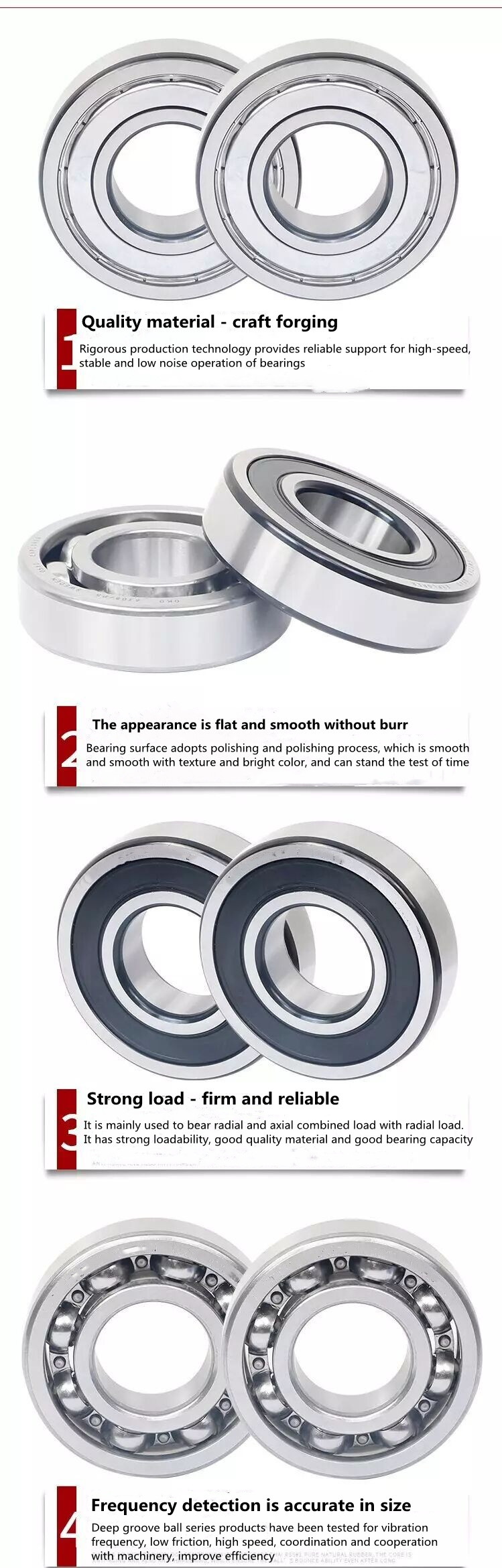

Pontšo ea tlhahiso

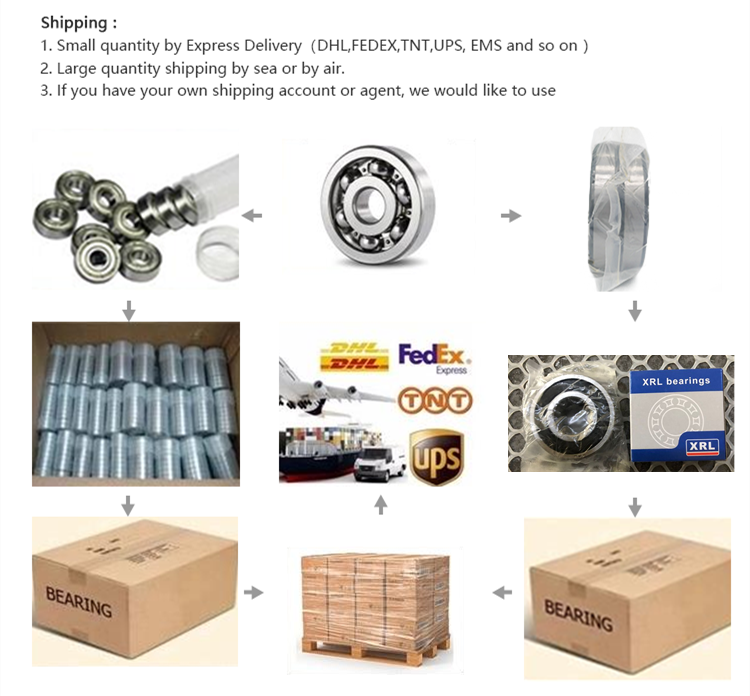

Ho tsamaisa ka sekepe

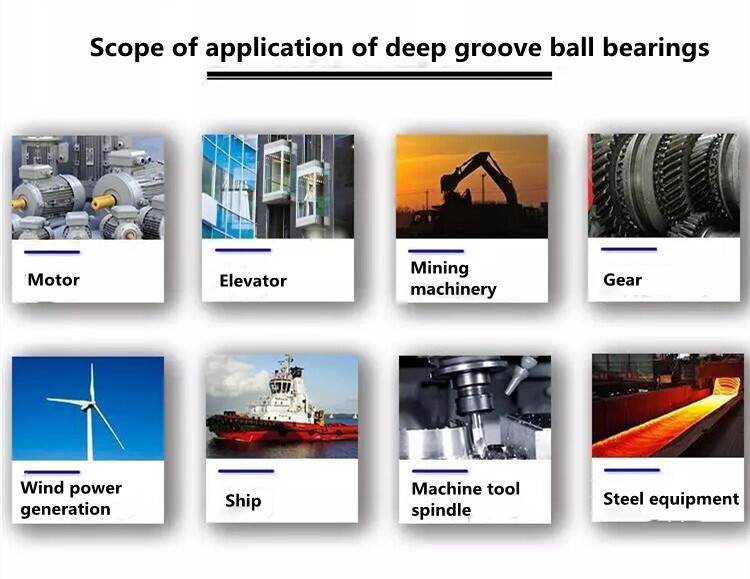

Kopo

Li-deep groove ball bearings li ka sebelisoa ka li-gearbox, lisebelisoa le limithara, li-motor, lisebelisoa tsa ntlo, lienjineri tse tukang ka hare, likoloi tsa sephethephethe, mechine ea temo, mechine ea kaho, mechine ea boenjiniere, li-roller skate tsa mofuta oa rolara, yo-yo, joalo-joalo.

Mekhahlelo

| E nang le No. | Boholo (mm) | Lintlha tsa mojaro (KN) | Boima(kg) | |||||||

| d | D | B | rmin | r1min | Dynamic Cr | Nete ea Cor | ||||

| 6403 | 17 | 62 | 17 | 1.1 | 0.5 | 22..500 | 10.800 | 0.2680 | ||

| 6404 | 20 | 72 | 19 | 1.1 | 0.5 | 31.000 | 15.200 | 0.4000 | ||

| 6405 | 25 | 80 | 21 | 1.5 | 0.5 | 38.200 | 19.200 | 0.5290 | ||

| 6406 | 30 | 90 | 23 | 1.5 | 0.5 | 47.500 | 24.500 | 0.7100 | ||

| 6407 | 35 | 100 | 25 | 1.5 | 0.5 | 56.800 | 29.500 | 0.9260 | ||

| 6408 | 40 | 110 | 27 | 2.0 | 0.5 | 65.500 | 37.500 | 1.2210 | ||

| 6409 | 45 | 120 | 29 | 2.0 | 0.5 | 77.500 | 45.500 | 1.5210 | ||

| 6410 | 50 | 130 | 31 | 2.1 | 0.5 | 92.200 | 55.200 | 1.8550 | ||

| 6411 | 55 | 140 | 33 | 2.1 | 0.5 | 100.60 | 62.500 | 2.3160 | ||

| 6412 | 60 | 150 | 35 | 2.1 | 0.5 | 109.10 | 70.000 | 2.8110 | ||

| 6413 | 65 | 160 | 37 | 2.1 | 0.5 | 118.14 | 78.570 | 3.3420 | ||

| 6414 | 70 | 180 | 42 | 3.0 | 0.5 | 139.50 | 99.560 | 4.8960 | ||

| 6415 | 75 | 190 | 45 | 3.0 | 0.5 | 153.78 | 114.32 | 5.7390 | ||

| 6416 | 80 | 200 | 48 | 3.0 | 0.5 | 163.22 | 124.55 | 6.7520 | ||

| 6417 | 85 | 210 | 52 | 4.0 | 174.90 | 137.49 | 7.9330 | |||

| 6418 | 90 | 225 | 54 | 4.0 | 192.48 | 157.63 | 9.5650 | |||

| 6419 | 95 | 240 | 55 | 4.0 | 206.00 | 171.00 | 11.200 | |||

| 6420 | 100 | 250 | 58 | 4.0 | 223.08 | 194.61 | 12.904 | |||

| 6300 | 10 | 35 | 11 | 0.6 | 0.5 | 7.6500 | 3.4700 | 0.053 | ||

| 6301 | 12 | 37 | 12 | 1.0 | 0.5 | 9.7200 | 5.0900 | 0.057 | ||

| 6302 | 15 | 42 | 13 | 1.0 | 0.5 | 11.440 | 5.4300 | 0.081 | ||

| 6303 | 17 | 47 | 14 | 1.0 | 0.5 | 13.580 | 6.5800 | 0.109 | ||

| 6304 | 20 | 52 | 15 | 1.1 | 0.5 | 15.940 | 7.8800 | 0.142 | ||

| 63/22 | 22 | 56 | 16 | 1.1 | 0.5 | 18.390 | 9.2400 | 0.184 | ||

| 6305 | 25 | 62 | 17 | 1.1 | 0.5 | 22.380 | 11.490 | 0.219 | ||

| 63/28 | 28 | 68 | 18 | 1.1 | 0.5 | 24.990 | 13.880 | 0.284 | ||

| 6306 | 30 | 72 | 19 | 1.1 | 0.5 | 27.000 | 15.190 | 0.350 | ||

| 63/32 | 32 | 75 | 20 | 1.1 | 0.5 | 29.800 | 16.900 | 0.382 | ||

| 6307 | 35 | 80 | 21 | 1.5 | 0.5 | 33.360 | 19.210 | 0.454 | ||

| 6308 | 40 | 90 | 23 | 1.5 | 0.5 | 40.750 | 24.010 | 0.639 | ||

| 6309 | 45 | 100 | 25 | 1.5 | 0.5 | 52.860 | 31.830 | 0.836 | ||

| 6310 | 50 | 110 | 27 | 2.0 | 0.5 | 61.860 | 37.940 | 1.082 | ||

| 6311 | 55 | 120 | 29 | 2.0 | 0.5 | 71.570 | 44.760 | 1.368 | ||

| 6312 | 60 | 130 | 31 | 2.1 | 0.5 | 81.750 | 51.850 | 1.710 | ||

| 6313 | 65 | 140 | 33 | 2.1 | 0.5 | 93.870 | 60.440 | 2.097 | ||

| 6314 | 70 | 150 | 35 | 2.1 | 0.5 | 104.13 | 68.040 | 2.543 | ||

| 6315 | 75 | 160 | 37 | 2.1 | 0.5 | 113.42 | 76.800 | 3.046 | ||

| 6316 | 80 | 170 | 39 | 2.1 | 0.5 | 122.94 | 86.500 | 3.609 | ||

| 6317 | 85 | 180 | 41 | 3.0 | 0.5 | 132.67 | 96.580 | 4.284 | ||

| 6318 | 90 | 190 | 43 | 3.0 | 0.5 | 144.05 | 108.49 | 4.979 | ||

| 6319 | 95 | 200 | 45 | 3.0 | 0.5 | 156.66 | 121.98 | 5.740 | ||

| 6320 | 100 | 215 | 47 | 3.0 | 0.5 | 172.98 | 140.39 | 7.090 | ||